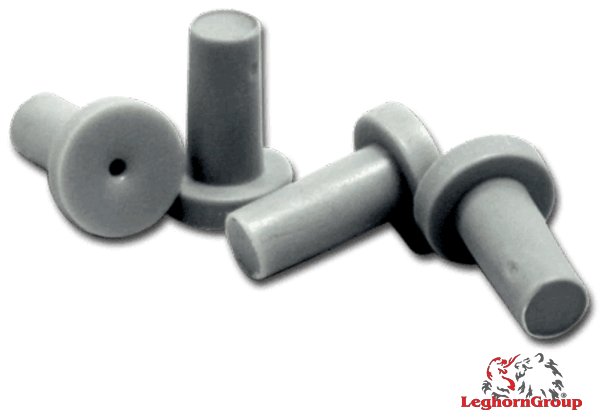

Plastic injection moulding

Plastic injection moulding

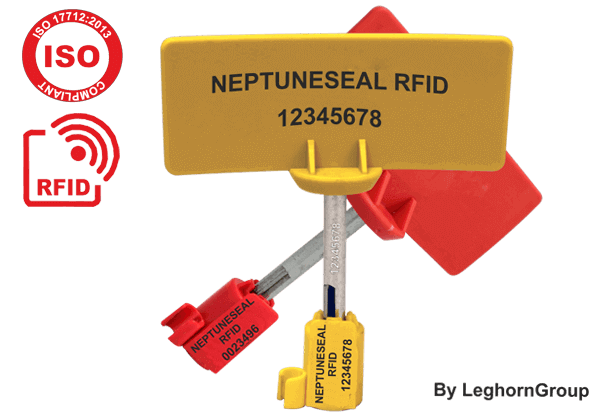

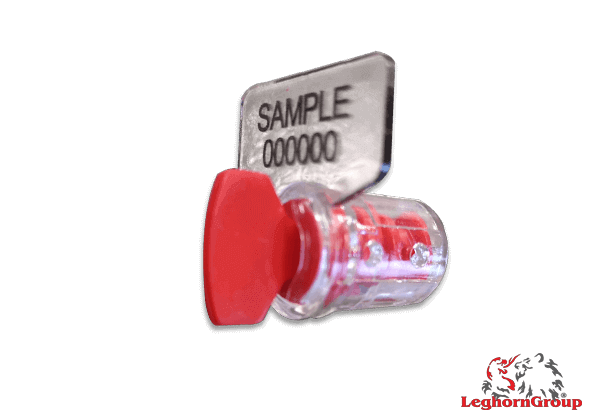

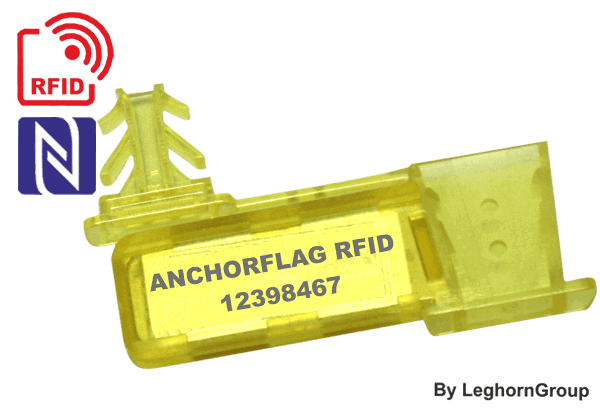

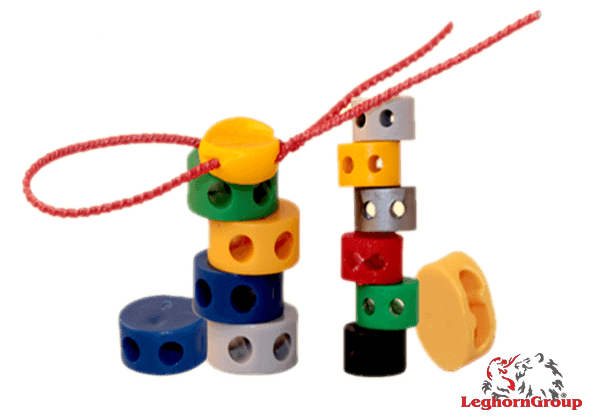

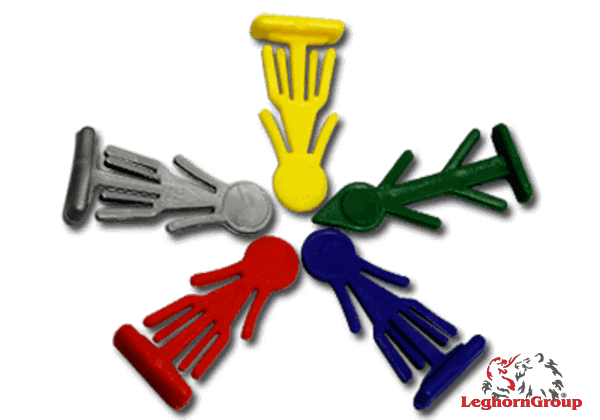

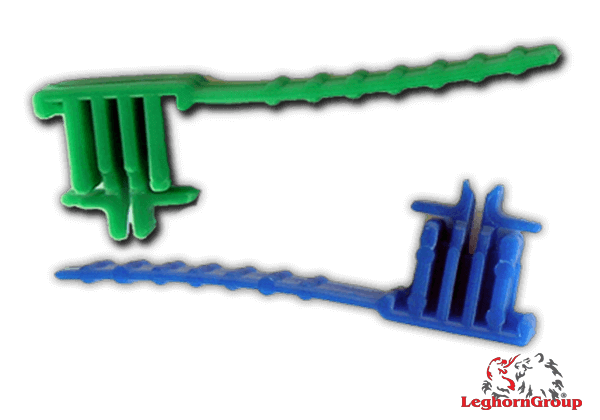

Thanks to its production companies, LeghornGroup handles all type of high-quality plastic materials. We are able to print heterogeneous material and process them both with industrial and semi-craft techniques, providing the customer with the best product for his requirements.

Analysis and design

Analysis and design

Both the project that has to be implemented with plastic materials and the type of mould are carefully analysed. Moulds therefore undergo several checks and tests in order to offer a high level end product. Furthermore, to reduce the product final costs, LeghornGroup is constantly engaged in researching and developing innovative solutions to provide its customers the best outcome with as little effort as possible. We offer a unique perspective in plastic injection moulding and product design. With decades of experience managing and designing injection moulds, LeghornGroup is able to suggest the customer for the different printing options together with the choice of the best product that meets his requirements.

Both the project that has to be implemented with plastic materials and the type of mould are carefully analysed. Moulds therefore undergo several checks and tests in order to offer a high level end product. Furthermore, to reduce the product final costs, LeghornGroup is constantly engaged in researching and developing innovative solutions to provide its customers the best outcome with as little effort as possible. We offer a unique perspective in plastic injection moulding and product design. With decades of experience managing and designing injection moulds, LeghornGroup is able to suggest the customer for the different printing options together with the choice of the best product that meets his requirements.

We bring your ideas to life

We bring your ideas to life

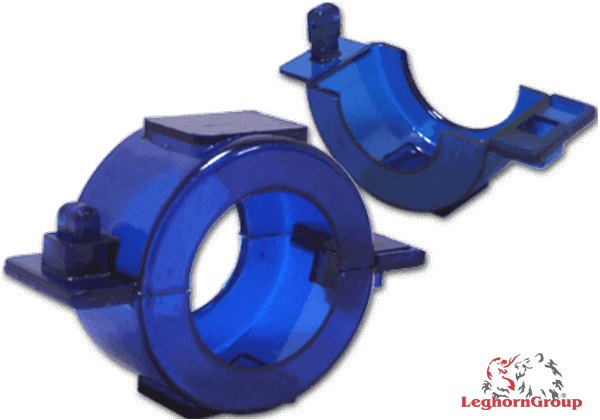

All the technicians and engineers of LeghornGroup pay carefully attention to customer’s needs and are always available to find new solutions to improve the end product. As a result, we implement moulds that guarantee long lasting products.

Time and cost savings

Time and cost savings

Choosing the right materials for moulding, evaluating costs and processing times, allows us to provide the customer a real cost and time saving together with speed and accuracy in mould design. Great efficiency in printing seals and deliveries within agreed terms, make us the ideal partner for facing an ever more competitive market.

Service

Service

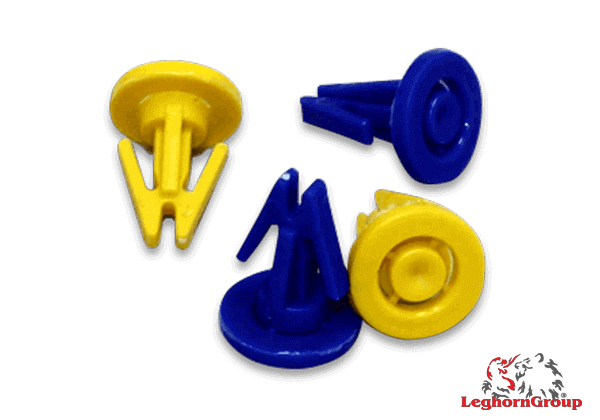

LeghornGroup is one of the few companies that can manage the entire production process.

– Producing the moulds

– Moulding

– Assembling

– Planning and analysing

– JUST IN TIME